Arced:

Visible effects (burn spots, fused metal) of an undesired electrical discharge between two electrical connections.

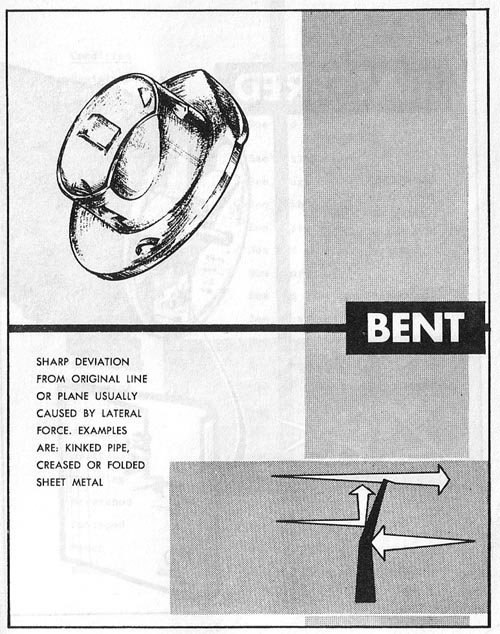

Bent:

Binding:

Restricted movement such as tightened or sticking condition resulting from high or low temperature, foreign object jammed in mechanism, etc.

Burrs:

A rough edge or a sharp projection on the edge or surface of the parent material.

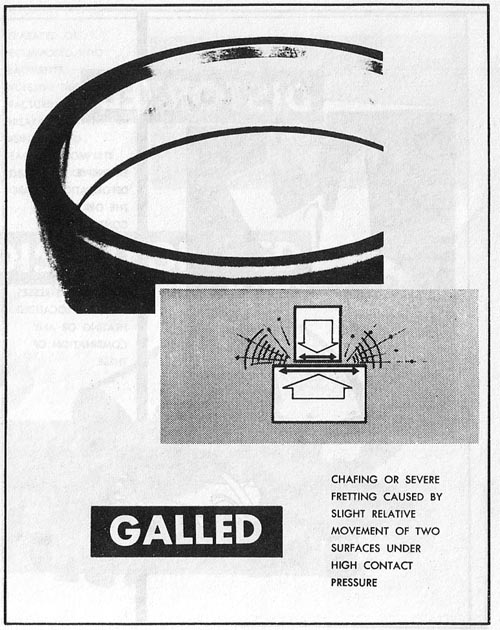

Chafed:

Frictional wear damage usually caused by two parts rubbing together with limited motion.

Checked:

Surface cracks usually caused by heat.

Chipped:

A breaking away of the edge corner or surface of the parent material usually caused by heavy impact (not flaking).

Circuit – Grounded:

Undesired current path to ground (common).

Circuit – Open:

Incomplete electrical circuit due to separation at or between electrical connection points.

Circuit – Shorted:

Undesired current path between leads or circuits that normally are at a different potential.

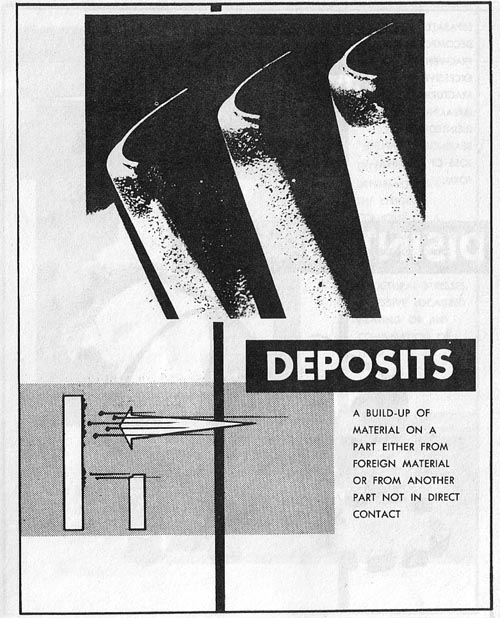

Corroded:

Gradual destruction of the parent material by chemical action. Often evidenced by oxide build-up on the surface of the parent material.

Crossed:

Material damage to parts (as in the case of crossed threads) or part rendered inoperative (as in the case of crossed wires) as a result of improper assembly.

Eccentric:

Part(s) wherein the intended common center is displaced significantly.

Eroded:

Carry away of material by flow of fluids or gases, accelerated by heat or grit.

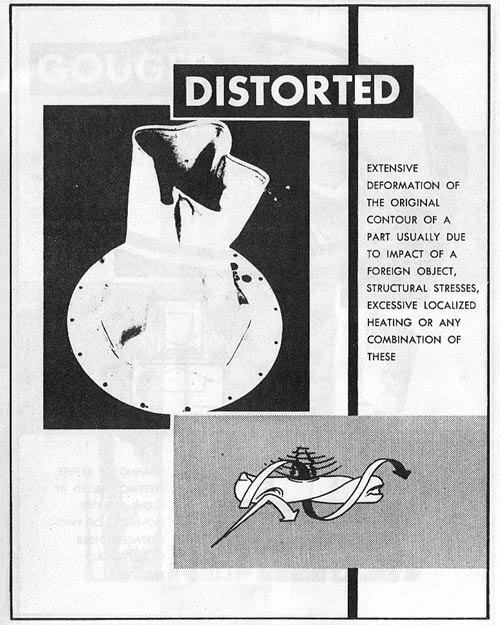

Flattened out:

Permanent deformation beyond tolerance limits usually caused by compression.

Frayed:

Worn into shreds by rubbing action.

Fused:

Joining together of two materials usually caused by heat, friction, or current flow.

Glazed:

Undesirable development of a hard, glossy surface due to rubbing action, heat or varnish.

Indications:

Cracks, inclusions, fractures etc. not visible without fluorescent or magnetic penetrants.

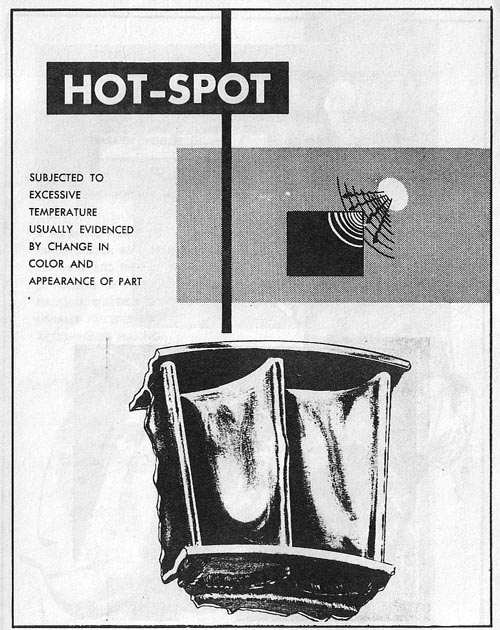

Melted:

Deformation from the o-riginal configuration due to heat, friction or pres-sure as with melted bear-ings or insulation.

Mis-matched:

Improper association of two or more parts.

Mis-aligned:

Improper installation of a part resulting in damage to the installed part or to associated parts.

Plugged:

Pipe, hoses, tubing, channeling, internal passage etc. which are totally or partially blocked.

Rough:

Usually applies to operation as opposed to surface finish; i.e. a condition of bearings (which cannot be disassembled further) where during the spin test the rotation is rough.

Rubbed:

To move with pressure or friction against another part such as compressor rub.

Rust:

Sometimes written down when corrosion is found. Applies only to some specific persons. If “rust” is found, no aircraft will ever leave the hangar.

Seized:

Parts bound together because of expansion or contraction due to high or low temperature, foreign object jammed in mechanism, etc.

Streched:

Enlargement of a part as a result of exposure to operating conditions.+

Stripped:

A condition usually associated with threads or insulation. Involves removal of material (threads) by force.

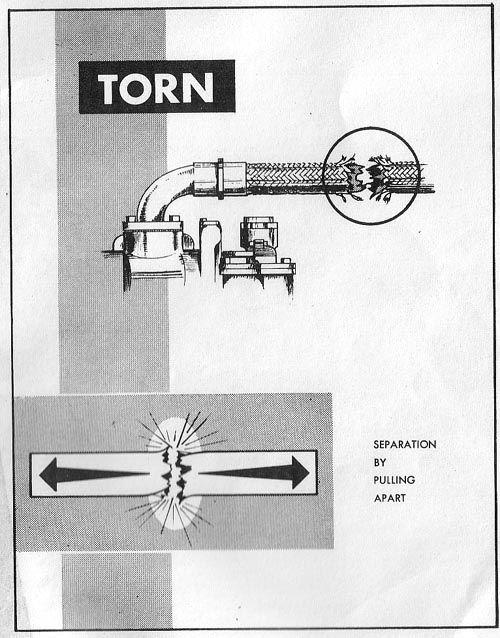

Torn:

Worn excessively:

Material of part consumed as a result of exposure to operation or usage, beyond the limits given by the manufacturer.

> FOR INFORMATION ONLY. UNCONTROLLED DATA !.